- What is polypropylen...2024/9/2

- The operation of the...2024/9/2

- Work together for wi...2024/8/30

- The operation of the...2024/8/26

- Polypropylene fine d...2024/8/26

On December 24th, the 2019 annual meeting of the polypropylene branch and the forum on the transformation of the polypropylene industry and promotion of development were held in Jiaxing, a revolutionary shrine.

The conference was hosted by the China Chemical Fiber Industry Association, and organized by the China Chemical Fiber Industry Association Polypropylene Branch, Jiaxing Shengbang Machinery Equipment Co., Ltd., Guangdong Mengtai High-tech Fiber Co., Ltd., Jiaxing College, and China Polypropylene Network.

Jiangjun Zhou, Vice Chairman of the China Chemical Fiber Industry Association, Guo Qinghai, Chairman of the Polypropylene Branch of the China Chemical Fiber Industry Association (General Manager of Guangdong Mengtai High-tech Fiber Co., Ltd.), Professor Chen Long of Donghua University, Professor Yi Honglei of Jiaxing University, and More than 200 representatives of entrepreneurs, experts in the polypropylene industry chain, universities and research institutes attended the meeting.

leader's speech

Jiang Junzhou, vice chairman of the China Chemical Fiber Industry Association, said in his speech that since the founding of the People's Republic of China for 70 years, China's chemical fiber industry has been facing strategic opportunities for international industrial transfer. At present, the output of conventional chemical fiber products ranks first in the world, and most of the high-performance fiber and bio-based fiber products are in the forefront of the world, achieving a fundamental change from a single variety, relying on imports to complete varieties and a large number of exports. China's chemical fiber industry has formed a complete industrial system, comprehensively enhanced comprehensive competitiveness, and has become an industry with international competitive advantages. It is an important pillar industry for the overall competitiveness of the textile industry and an important part of China's strategic emerging industries.

Jiang Junzhou pointed out that polypropylene is a small variety in the chemical fiber industry. Most polypropylene enterprises are private enterprises. According to the National Bureau of Statistics of China, the production of polypropylene in 2018 was 348,800 tons (the actual output is about 700,000 tons due to statistical caliber problems, excluding membranes). Cracked fiber and meltblown non-woven fabric), stable at about 300,000 tons for more than ten years. Polypropylene production process is green and environmentally friendly, with excellent product performance, light weight, high strength, and good acid and alkali resistance. It is widely used in clothing, decoration, carpet and industrial fields. However, due to the small scale of the industry and the insufficient progress in equipment technology, polypropylene has maintained a steady development trend in specific application areas. At present, the international economic and trade environment is complicated, and risks at home and abroad have increased significantly. In the face of a complex economic situation, the Fourth Plenary Session of the 19th CPC Central Committee emphasized the need to better transform the advantages of the system into the effectiveness of governance. Strengths and weaknesses. Facing the new situation and new situation, this requires the polypropylene industry to do something in promoting the supply-side structural reform of the industry. The polypropylene industry should seize a new round of scientific and technological revolution and industrial revolution that are cultivating favorable opportunities, vigorously implement the innovation-driven strategy, improve the innovation mechanism, and comprehensively promote system innovation, scientific and technological innovation, product innovation, market innovation, brand innovation, and actively explore high quality. R & D and application of multi-functional polypropylene products, strive to open up the application of polypropylene in the fields of clothing, apparel and industrial use, expand new application areas, and develop new market space; accelerate industrial structure adjustment, optimize inventory structure, eliminate backward production capacity, and promote The upgrading of manufacturing equipment explores opportunities for innovation and development in promoting the high-quality development of the polypropylene industry.

In the end, he hoped that at the annual meeting of the polypropylene branch and the forum on the efficiency and promotion of the development of the polypropylene industry, experts and entrepreneurs in the polypropylene industry could provide suggestions and suggestions to jointly promote the innovative development of the polypropylene industry.

Guo Qinghai, chairman of the China Chemical Fiber Industry Association's polypropylene branch (general manager of Guangdong Modern High-tech Fiber Co., Ltd.) pointed out in his speech that since the "13th Five-Year Plan" period, the polypropylene industry has achieved some remarkable achievements: First, The monopoly pattern has been broken. As private enterprises enter the refining and chemical industry and the development of propane dehydrogenation and other olefin technologies, they have provided sufficient raw material guarantees for the polypropylene industry. Second, the industry structure has been continuously optimized, the industry concentration has been continuously improved, and the product structure has become more Adapt to market demand; the third is the further acceleration of polypropylene filament equipment technology, which is conducive to the industry's technological transformation and innovation and upgrading, and strengthen product competitiveness; the fourth is the industrialization breakthrough of polypropylene recycling technology, which not only achieves resource regeneration, but also helps protect Environment; Fifth, energy saving and emission reduction have achieved good results, and the original liquid coloring technology has become more mature, reducing wastewater discharge.

He also briefly introduced some achievements and advanced experience of Guangdong Mengtai High-tech Fiber Co., Ltd. in the development of new polypropylene products and production management.

He said that today the exchange will focus on the conversion efficiency, industrial upgrading, high-quality development, market operation, technological innovation, new product development, green development and other aspects of the polypropylene industry. In order to promote the high-quality development of the polypropylene industry, we will make our generation of polypropylene. Human effort!

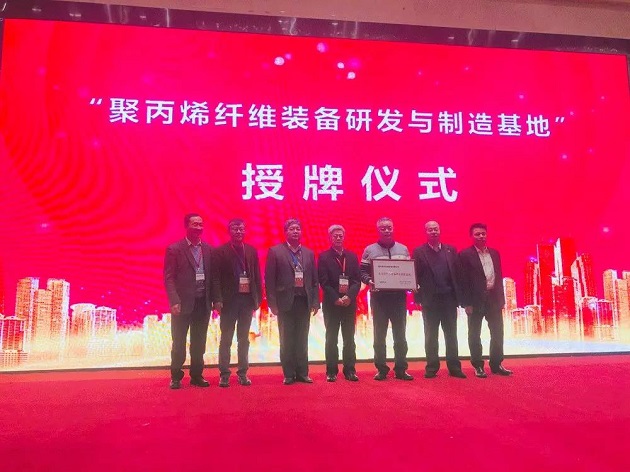

Licensing ceremony

During the meeting, the ceremony of granting the title of "Polypropylene fiber equipment R & D and manufacturing base" to Jiaxing Shengbang Machinery Co., Ltd. was held.

Jiang Junzhou, vice chairman of China Chemical Fiber Industry Association, came to the stage to give a license to the company, and Li Changqi, general manager of Jiaxing Shengbang Machinery Co., Ltd. came to the stage to receive a license. Chairman of China Chemical Fiber Industry Association Polypropylene Branch (General Manager of Guangdong Mengtai High-tech Fiber Co., Ltd.) Guo Qinghai, Professor Chen Long of Donghua University, Professor Yi Honglei of Jiaxing College, Senior Researcher of Beijing Futures and Options Research Center Chun Yu and Secretary-General of the China Chemical Fiber Industry Association Polypropylene Branch Li Zengjun came to power to witness this moment.

Forum Report

Guo Renqi, the technical director of Guangdong Modern High-tech Fiber Co., Ltd., gave a speech on "Discussion on the Production Process of Fine Denier and Ultra-fine Denier Polypropylene DTY Filament".

The fine denier and ultra-fine denier polypropylene POY-DTY filaments are produced by melt spinning and texturing processes to produce filaments with a monofilament of about 1D, which improves the feel and softness of polypropylene, thereby meeting the requirements of apparel fabrics and promoting Application and development of polypropylene.

Guo Renqi, the technical director of Guangdong Mengtai High-tech Fiber Co., Ltd., and the polypropylene industry practitioners on the spot discussed the use of polypropylene chips as raw materials to produce POY through melt spinning, and fine-denier and ultra-fine-denier polypropylene DTY lengths were obtained through a two-step method of texturing. Silk craft.

He introduced in detail the effects of polypropylene raw materials, spinning equipment, spinning temperature, component pressure and spinning speed, and texturing process on fine denier and ultra-fine denier polypropylene DTY filament production and DTY performance. He pointed out that drying is a basis for ensuring the moisture content of the chips and the stability of spinning; reasonable spinning temperature and optimized component configuration are conducive to the consistent viscosity of PP and the stability of fluidity, which is good for stable spinning and excellent and stable POY quality. ; Appropriate oiling device, side blowing conditions and overfeeding of spinning speed are conducive to normal spinning and molding; a reasonable texturing process is conducive to the production of high-quality fine denier and ultra-fine denier polypropylene DTY filament fibers.

"Technical Status and Development Trend of Polypropylene Fiber"

Professor Chen Long, Deputy Director of Collaborative Innovation Center, Donghua University

"Impact of Polypropylene (PP) Futures on the Domestic Polypropylene Industry"

Gao Chunyu, Senior Researcher, Beijing Futures and Options Research Center

"Talking about the development of polypropylene industry from the development trend of polyester and polyamide fiber industry"

Dr. Ji Peng, Textile Collaborative Innovation Center, Donghua University

《Application and Development of Polypropylene Industrial Fibers》

Professor Yan Zhiyong of Jiaxing University

"Innovative Development of Polypropylene Manufacturing Technology"

Li Changqi, General Manager of Jiaxing Shengbang Machinery Equipment Co., Ltd.

"The latest development and application of polypropylene functional masterbatch"

Zhang Tangjun, Deputy General Manager of Production, Zhejiang Jincai New Material Co., Ltd.

"New Domestic Equipment and Application of New Technology"

Man Xiaodong, Senior Engineer, Beijing Zhongli Machinery Engineering Technology Co., Ltd.

As the organizer of this annual polypropylene conference, Modern is very happy to join the event with industry elites to discuss hot issues in the development of the industry and share its production technology and experience.

Over the years, Modern has never forgotten its original intention, devoted itself to the field of polypropylene fiber, technological innovation, creating high-quality products, and providing customers with quality products and services.

Thank you for your continued attention and support for Monte Thai. In the future, Modern will continue to work hard to use its strong innovation capabilities and professional production technology to ingeniously cast more fiber products that meet customer needs, and contribute its strength to the development of the polypropylene industry!